Search for the product you are looking for

Product Category

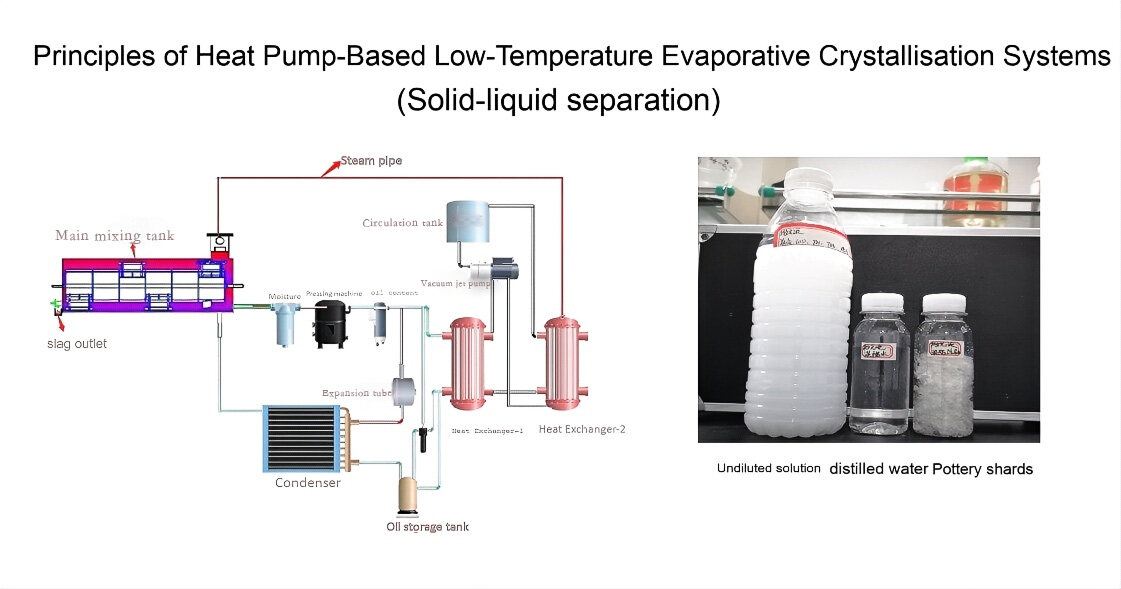

Low-temperature evaporation crystallisation equipment

-

Online Consultation

National Service Hotline

Product Details

Product Features

This equipment operates fully automatically. When the wastewater tank reaches the mid-level, the evaporator automatically feeds water. The pump creates a vacuum, while the compressor generates heat to warm the wastewater within the evaporator tank.

Under vacuum conditions, the wastewater temperature rises to 30°C, initiating evaporation and completing the preheating phase.

The evaporation temperature is set to 37°C. The compressor compresses Freon to generate heat, rapidly evaporating moisture. Simultaneously, Freon vaporises through the expansion valve, absorbing heat for refrigeration. The vapour rises, encounters the cold liquid, liquefies, and enters the storage tank. Having absorbed heat, the Freon is compressed by the compressor to generate heat, reheating the wastewater.

Should bubbles rise during evaporation, sensors detect them and automatically introduce defoaming agent to eliminate foam. Upon completion of one cycle, crystallised material begins discharge. (Cycle duration is configurable.)

Following an evaporation cycle, the compression pump ceases operation. The pneumatic valve at the discharge port opens, and the evaporator tank discharges crystallised material into the residue collection drum via rotating scrapers.

How it works

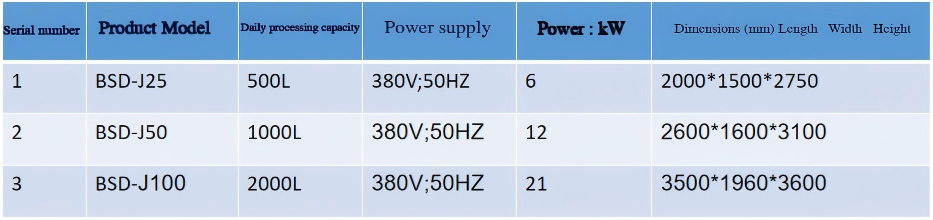

Product Parameters